All Types of Conveyor's System

Conveyor systems are essential in various industries for transporting materials efficiently.

Our Products

Previous slide

Next slide

Conveyor Systems: Streamlining Your Operations

In today’s fast-paced industrial landscape, efficiency and reliability are paramount. Conveyor systems are the backbone of many industries, enabling the smooth and efficient transportation of materials and products. At Unique Packaging, we offer a wide range of conveyor systems tailored to meet the diverse needs of our clients. From heavy-duty applications to lightweight handling, we have the perfect solution for your operational requirements

Types Of Conveyor System -

- Belt Conveyor

Belt conveyor is an efficient and versatile machine used to transport materials across distances in industries like mining, agriculture, and manufacturing. Made of a continuous belt loop, it moves materials smoothly over pulleys and can be customized with different belt types and added safety features. Known for low operating costs and high throughput, belt conveyors handle materials of various sizes and weights with ease. They are ideal for applications that require long-distance transport, minimal maintenance, and energy efficiency.

- Flexible Chain Conveyor

Flexible chain conveyor is a specialized material handling system designed for easy, adaptable movement along complex paths, including curves, inclines, and declines. Unlike traditional conveyors, its flexible chain allows smooth transport through tight spaces and around corners, making it ideal for industries with complex layouts like packaging, pharmaceuticals, and automotive. This conveyor is highly customizable with various chain types, load capacities, and attachments, providing precise control and efficient space utilization. Its modular design also allows for easy adjustments, quick reconfiguration, and minimal maintenance, enhancing efficiency and adaptability.

- Roller Conveyor

Roller conveyor is a simple yet effective system for moving materials, commonly used in warehouses, manufacturing, and distribution centers. It consists of a series of rollers that can be powered or gravity-driven, allowing goods to roll along the conveyor path with ease. Roller conveyors are ideal for transporting heavy or rigid items like boxes, pallets, and containers. They offer easy scalability and flexibility, allowing for adjustments in length or direction, and are known for their low maintenance needs. Additionally, roller conveyors support smooth, controlled handling and can integrate seamlessly with automated systems.

- Screw Conveyor

Screw conveyor is a robust and efficient system used to move bulk materials in industries like agriculture, mining, and food processing. It consists of a helical screw blade, or auger, that rotates within a tube or trough, pushing materials like grains, powders, or semi-solids along its length. Ideal for moving materials over short distances or at an incline, screw conveyors offer controlled handling with minimal spillage. They’re compact, require little maintenance, and are customizable in length, material type, and diameter to suit various processing needs.

- Pneumatic Conveyor

Pneumatic conveyor efficiently transports bulk materials like powders and granules through pipelines using air or gas pressure, ensuring a dust-free, enclosed environment ideal for food, chemical, and pharmaceutical industries. This system allows flexible routing—vertical, horizontal, and over long distances—making it suitable for complex layouts. Highly customizable with filters, automated controls, and hoppers, pneumatic conveyors provide safe, contamination-free material handling that enhances productivity while minimizing maintenance.

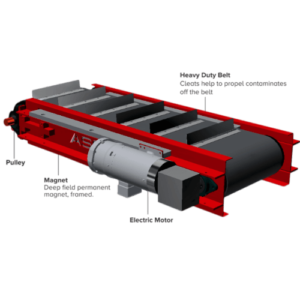

- Magnetic Conveyor

Magnetic conveyor uses powerful magnets beneath the conveyor surface to securely transport ferrous materials, like metal parts or scrap, across horizontal or inclined paths. Ideal for manufacturing, recycling, and metalworking industries, this conveyor system ensures safe, controlled movement, reducing spillage and improving workflow efficiency. Magnetic conveyors are customizable in belt speed, length, and magnet strength, allowing for precise handling of materials. They’re low-maintenance, prevent jamming, and can work in environments with high temperatures, making them a reliable choice for heavy-duty operations.

- Z-Conveyor

Z-conveyor, also known as a Z-type conveyor or bucket elevator, is designed to transport bulk materials vertically and horizontally in a continuous motion. Its unique Z-shape allows for efficient space utilization, making it ideal for handling products like grains, powders, and packaged goods.

- Bucket Elevator

Bucket elevator is an efficient vertical conveying system used to move bulk materials like grains, cement, and minerals. Equipped with a series of buckets attached to a belt or chain, it lifts materials from a lower level to a higher level, often within silos or storage facilities. Bucket elevators are widely used in agriculture, construction, and mining due to their ability to handle large volumes, save space, and maintain continuous material flow. They are ideal for transporting both dry and wet materials, making them versatile and essential for high-capacity, space-saving vertical material transport.

- Vibrating Conveyors

Vibrating conveyors are efficient systems for moving bulk materials through controlled vibrations, ideal for industries like food processing, mining, and agriculture. They provide gentle handling for delicate items, energy efficiency for short-distance transport, and precise control of material flow. Though typically limited to shorter distances and sometimes producing noise, their low maintenance and reliability make them essential for applications that require steady and uniform material movement.

- Overhead Conveyor

Overhead conveyor systems are efficient material handling solutions designed to transport goods along a track above ground, maximizing floor space and enhancing operational flow. These systems offer numerous benefits, including increased productivity by reducing manual handling, space efficiency by freeing up valuable floor area, and cost-effectiveness through automation that lowers labor expenses. They come in various types, such as enclosed track conveyors for lighter loads, I-beam conveyors for heavier items, and power and free conveyors that allow for independent load movement. Commonly used in industries like automotive, food processing, and warehousing, overhead conveyors streamline processes in assembly lines and product distribution. Investing in these systems can significantly boost productivity and optimize space, making them a smart choice for modern businesses.

- Flexible Conveyor

Flexible conveyor systems are versatile material handling solutions designed to adapt easily to various layouts and workflows. Unlike traditional conveyors, they can be reconfigured to meet changing needs, making them ideal for facilities with limited space. These systems streamline operations by facilitating the easy movement of goods between different areas, significantly improving workflow efficiency. Many flexible conveyors are lightweight and portable, allowing for temporary setups or multi-use applications in warehouses, distribution centers, and manufacturing facilities. Overall, flexible conveyor systems enhance operational adaptability and efficiency, making them a valuable asset for businesses looking to optimize their material handling processes.

- Automated Guided Vehicles(AGV’s)

Automated Guided Vehicles (AGVs) are robotic systems designed to transport materials and products within facilities without human intervention. Utilizing various navigation technologies—such as lasers, magnets, and vision systems—AGVs move safely and efficiently along predefined paths. They significantly increase efficiency by streamlining material handling processes, reducing transportation time, and improving workflow. Additionally, AGVs lower labor costs and minimize human error by automating repetitive tasks. With built-in sensors and safety features, they enhance workplace safety by reducing accident risks. Widely used in manufacturing, warehousing, and distribution centers, AGVs excel in tasks such as transporting raw materials, finished products, and managing inventory. Overall, AGVs offer an efficient, safe, and cost-effective solution for modern material handling, making them an essential asset for businesses seeking to optimize their operations.

Types of Conveyor Systems

| Type | Description | Applications |

|---|---|---|

| Belt Conveyors | Versatile and widely used with a continuous belt for transporting materials. | Package handling, food processing, assembly lines. |

| Roller Conveyors | Comprise a series of rollers, allowing items to roll from one end to another. | Warehousing and distribution centers. |

| Chain Conveyors | Utilize a robust chain to move products along the conveyor, ideal for heavy-duty applications. | Automotive assembly and heavy manufacturing. |

| Screw Conveyors | Use a rotating screw blade to move bulk materials through a tube. | Agriculture, food processing, and powder handling. |

| Pneumatic Conveyors | Transport materials using air pressure through a system of tubes. | Food processing and pharmaceuticals. |

| Magnetic Conveyors | Move ferrous materials using magnets, providing efficient transport. | Metal stamping and parts handling. |

| Z-Conveyors | Allow for elevation changes, moving products in a “Z” shape. | Optimizing space between different levels. |

| Bucket Elevators | Lift bulk materials vertically using attached buckets. | Grain handling, mining, and chemical processing. |

| Vibrating Conveyors | Move materials along a trough using vibrations, suitable for bulk material handling. | Foundry applications. |

| Overhead Conveyors | Suspend materials from a track, freeing up floor space while maximizing efficiency. | Paint shops, assembly lines, and warehouse systems. |

| Flexible Conveyors | Easily movable and reconfigurable, ideal for temporary setups. | Warehouses and shipping areas. |

| Automated Guided Vehicles (AGVs) | Provide modern material transport solutions using autonomous navigation. | Warehousing and material transport in manufacturing. |