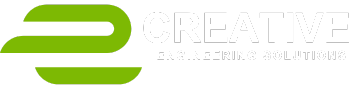

Fully Automatic Filling Machine

Our Fully Automatic Filling Machines are designed to meet the high-speed, precision demands of modern production lines.

Our Products

Fully Automatic Filling Machines: Precision, Speed, and Efficiency

At Creative Engineering Solutions, our Fully Automatic Filling Machines are engineered to optimize your production line and meet the rigorous demands of today’s fast-paced industries. Whether you’re in the food and beverage, pharmaceutical, cosmetic, or chemical industry, our filling machines deliver accurate and high-speed filling for liquids, powders, and granules.

At Creative Engineering Solutions, our Fully Automatic Filling Machines are engineered to optimize your production line and meet the rigorous demands of today’s fast-paced industries. Whether you’re in the food and beverage, pharmaceutical, cosmetic, or chemical industry, our filling machines deliver accurate and high-speed filling for liquids, powders, and granules.

Why Choose Our Fully Automatic Filling Machines?

- High-Speed Performance: Our machines are designed to handle high-volume production, ensuring quick and precise filling every time. Increase your production capacity while maintaining the highest standards of accuracy.

- Versatile Applications: From liquids to powders, our filling machines can handle a wide range of products, offering flexibility for different viscosities and container types, including bottles, jars, and pouches.

- Cutting-Edge Precision: Built with the latest technology, our filling systems ensure accurate fill levels, reducing product waste and improving overall operational efficiency.

- User-Friendly Interface: Featuring an intuitive control panel, our machines are easy to operate and maintain, allowing your team to minimize downtime and boost productivity.

- Customizable Solutions: We understand that every business has unique requirements, which is why our machines are fully customizable to fit your specific production needs. Whether it’s adapting to product types or adjusting fill levels, we have you covered.

Key Features

- High Speed and Efficiency

Fully automatic filling machines are designed for rapid operation, significantly increasing production rates and minimizing downtime. - Precision Filling

These machines ensure accurate fill volumes, reducing waste and ensuring product consistency across batches. - Versatility

Capable of handling a wide range of products—including liquids, powders, and granules—fully automatic filling machines can be adapted for various industries. - User-Friendly Interface

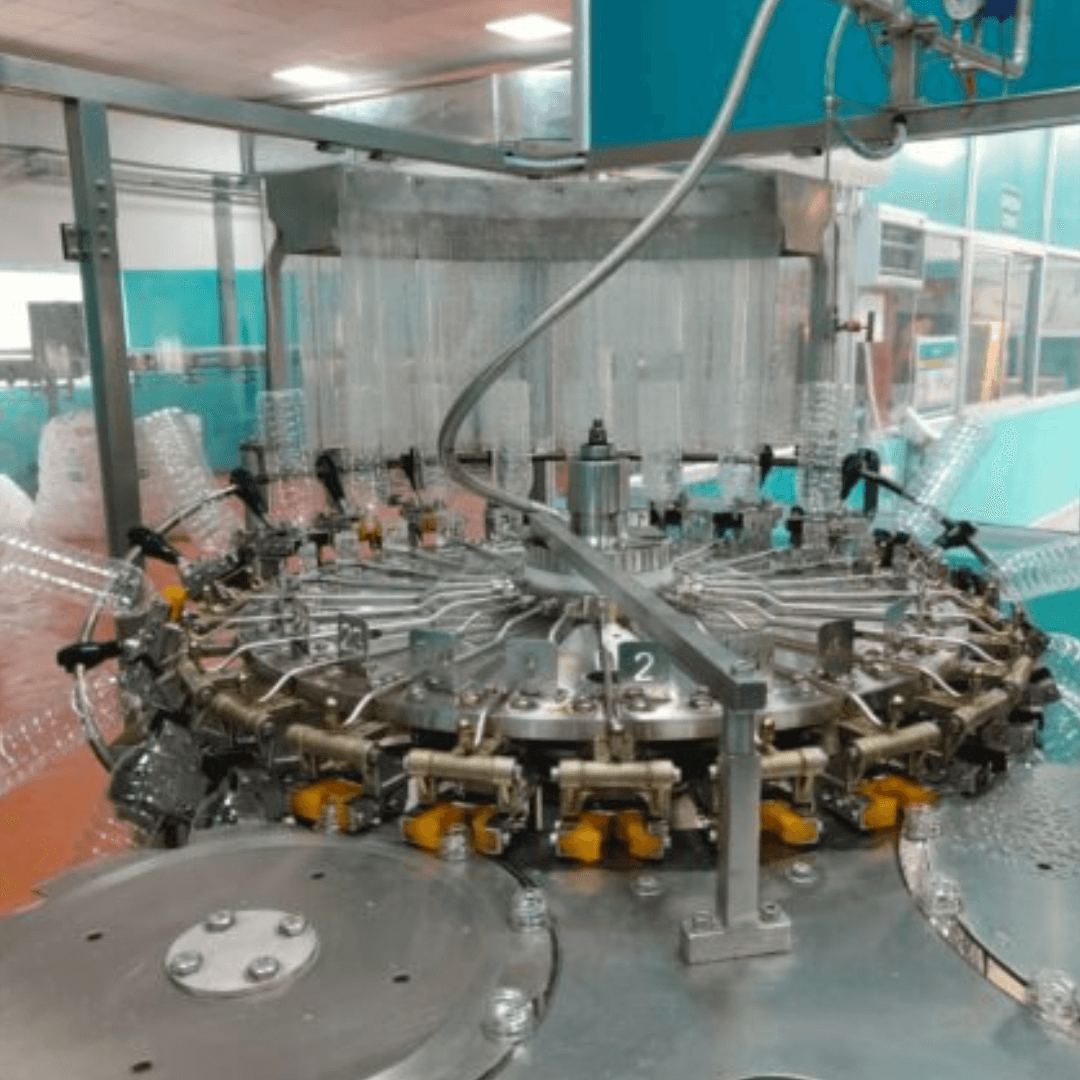

Equipped with intuitive control panels, these machines allow for easy operation and quick adjustments, enhancing usability for operators. - Automatic Cleaning Systems

Many models feature built-in cleaning cycles, reducing the need for manual cleaning and ensuring hygiene between product changes. - Robust Construction

Made from durable materials, these machines are built to withstand the rigors of high-volume production environments. - Safety Features

Incorporating safety mechanisms such as emergency stop buttons and safety guards, these machines protect operators and prevent accidents. - Integration Capabilities

Fully automatic filling machines can often be integrated with other packaging equipment, such as labeling and capping machines, creating a seamless production line. - Customizable Settings

Many machines allow users to customize filling parameters, accommodating different product viscosities and container sizes. - Data Logging and Monitoring

Advanced models may include features for tracking production data and monitoring machine performance, helping to optimize operations and maintenance.

Seamless Integration

Our Fully Automatic Filling Machines are designed for seamless integration with existing production lines, from conveyors to labeling systems. We provide comprehensive support to ensure a smooth installation process and ongoing maintenance for long-term reliability.